With the continuous advancement of science and technology, the digital transformation of water conservancy projects has become the key to improving the efficiency of urban water resource management and enhancing flood control capabilities. Today, we will guide you to gain an in-depth understanding of the construction plan for the safety monitoring and management system of medium and large-scale sluices in China, and explore how to use advanced technologies to ensure national water security and improve the intelligence level of water conservancy projects.

China has built more than 100,000 sluices with a flow rate of 5 m³/s or above, which play a crucial role in flood prevention and mitigation, water resource allocation, and ecological environment improvement. However, due to historical issues, many sluices have problems such as low standards, poor quality, and incomplete supporting facilities.

On November 12, 2024, the Operation and Management Department of the Ministry of Water Resources issued the Notice on Compiling the "15th Five-Year" Safety Monitoring Implementation Plan for Important Dikes and the Safety Monitoring Implementation Plan for Medium and Large-Scale Sluices (Yunguan Han 〔2024〕 No. 22), requiring water administrative departments at the provincial level and river basin management agencies to earnestly carry out the compilation of the safety monitoring implementation plan for medium and large-scale sluices during the "15th Five-Year" period.

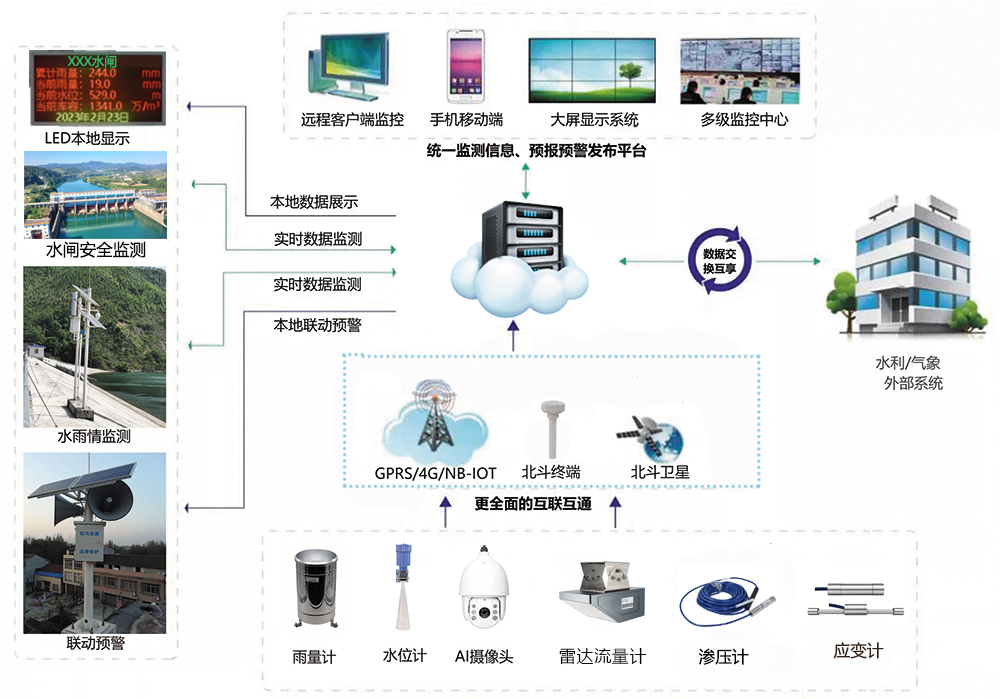

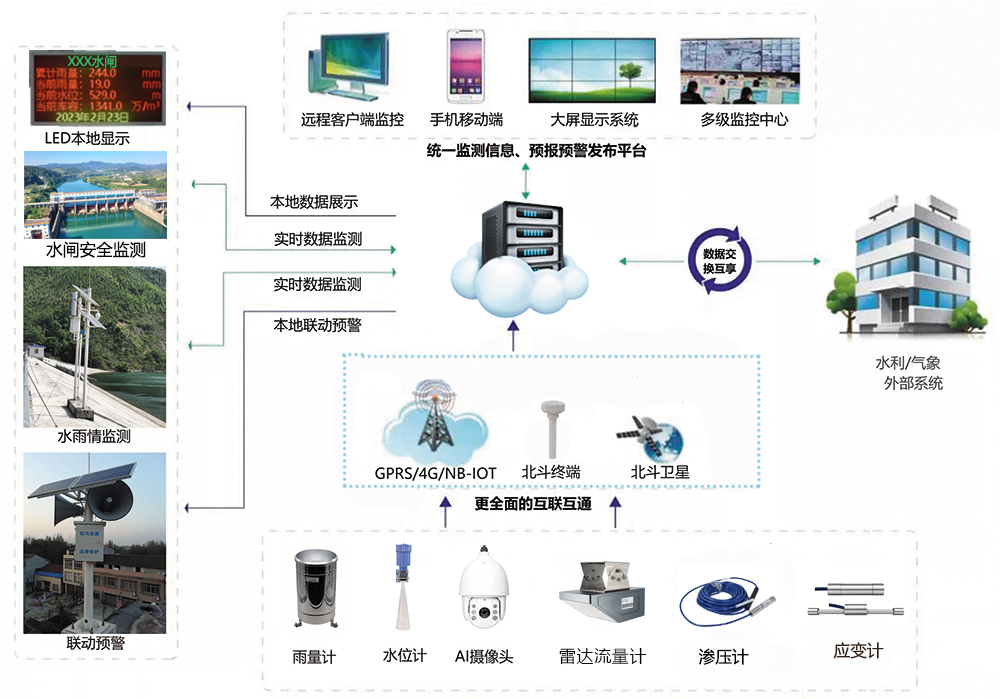

The safety monitoring system for medium and large-scale sluices is an integrated management system that combines functions such as sensor technology, data collection and processing, and remote monitoring and early warning. This system is designed to monitor the operating status of sluices in real time, detect potential safety hazards promptly, and ensure the safe and stable operation of sluices.

Sensor Network: Deployed at key parts of the sluice, such as gate leaves, hoists, and hinge supports, to monitor real-time parameters of the sluice including deformation, stress, and vibration.

Data Acquisition and Processing System: Responsible for collecting data transmitted by the sensor network, conducting preprocessing, storage, and analysis, and extracting key information for subsequent safety assessment.

Remote Monitoring Platform: Provides an intuitive user interface to display real-time monitoring data, historical data, and safety assessment results of the sluice, supporting remote operation and early warning functions.

Early Warning and Alarm System: Conducts real-time analysis of real-time monitoring data based on preset safety thresholds. When data anomalies occur, it triggers early warnings or alarms and promptly notifies relevant personnel to take measures.

█ Environmental Quantity Monitoring: It mainly includes water level, sluice discharge, rainfall, and meteorological monitoring. Using equipment such as radar water level gauges, radar flowmeters, and tipping-bucket rain gauges, real-time meteorological information, water level data, and water flow conditions are obtained to provide support for the scientific dispatching and safe operation of sluices.

Seepage monitoring includes uplift pressure monitoring, sluice pier seepage monitoring, and bypass seepage monitoring. Piezometers and seepage pressure gauges are installed to monitor the seepage status of the sluice structure, ensuring the stability of the sluice structure.

█ Stress and Strain Monitoring:Vibrating wire surface strain gauges are installed to measure the strain on the surface of the structure, and temperature is measured simultaneously to ensure the safe operation of the structure.

█ Deformation Monitoring:Deformation monitoring adopts a combination of manual observation and GNSS automated observation. Displacement information of each monitoring point is obtained through continuous observation and displayed on the system monitoring platform, allowing on-site personnel to grasp the structural status in real time.

Crack gauges are installed to monitor existing cracks on sluice piers, analyze the change rules of cracks, and ensure the stability and integrity of the sluice structure.

█ Gate and Hoist Status Monitoring:It monitors the opening degree of gates and the voltage/current of hoists in real time, and detects abnormal conditions and potential safety hazards during operation in a timely manner.

█ Video AI Monitoring:With high-definition cameras and intelligent recognition technology, it automatically identifies abnormal behaviors and sends out early warning signals promptly to prevent potential safety hazards.

█ Unmanned Automatic Patrol Inspection:The UAV autonomous inspection system realizes the fully automatic and uninterrupted inspection of hydraulic structures and landslides, meeting the needs of daily and emergency monitoring.

█ Real-Time Monitoring: The system can monitor various parameters of the sluice in real time, such as water level, flow rate, gate opening, stress, displacement, seepage, and vibration. Through real-time monitoring, staff can timely understand the operating status of the sluice and provide a basis for the dispatching and operation of the sluice.█ Data Analysis: The system can conduct in-depth analysis of the collected data and extract useful information. By analyzing the data, it is possible to understand the structural health status, operating status, and potential safety hazards of the sluice, providing a scientific basis for the safety assessment and maintenance of the sluice.

█ Early Warning and Alarm: When abnormal conditions are detected, the system can promptly send out early warning or alarm signals to remind staff to take corresponding measures for handling, so as to avoid the occurrence or escalation of accidents.

█ Remote Monitoring: The system supports the remote monitoring function. Staff can remotely access the monitoring center via the network to view the operating status and data of the sluice in real time. This helps improve work efficiency and reduce labor costs.

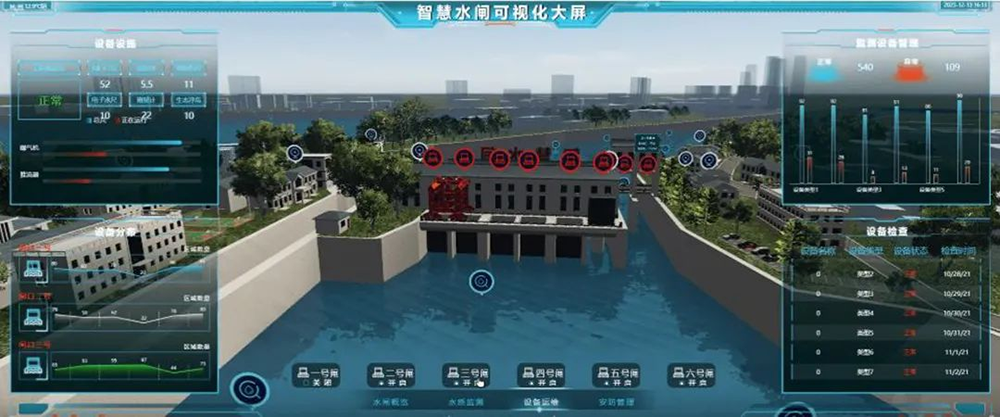

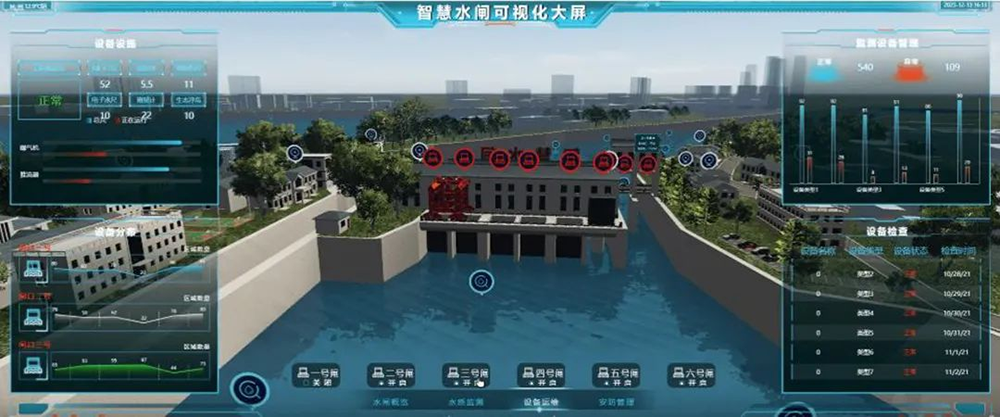

█ 3D Visualization: By constructing a 3D model of the sluice, real-time collection, analysis and visualization of data such as the sluice's operating status, water flow conditions and water level changes are realized. In this way, managers can understand the sluice's operating status more intuitively and improve management efficiency.

█ Historical Data Query: The system can record and store historical data, facilitating staff to query and compare at any time, understand the sluice's operating status and change trends over a period of time in the past, and provide references for future operation and maintenance.

█ Account Management and Data Security: The system is equipped with the function of separate account authorization management, granting different levels of management permissions according to the responsibilities of staff. Data transmission adopts an encryption mechanism to ensure data security.

█ Telemetry Terminal Unit (TTU) integrates the functions of traditional hydrological telemetry terminal units, 2G/3G/4G all-network communication/NB-IoT short-message wireless long-distance transmission, and LoRa wireless short-distance transmission. It realizes comprehensive functions such as collection, storage, transmission, display, control, alarm, and re-transmission of data in hydrology, water resources, geological disaster monitoring, meteorology, etc. Meanwhile, it supports GNSS positioning function.

This product adopts a high-performance industrial-grade 32-bit communication processor and industrial-grade wireless module, with an embedded real-time operating system as the software support platform. It also provides interfaces including a tipping-bucket rain gauge interface, RS232, RS485, SDI, wired network port, 4~20mA and 0~5V analog input, digital input, relay output, and digital output, which can meet the needs of various applications.

The product can be widely used in various water conservancy informatization construction fields, such as the remote measurement and control fields of hydrology, water resources, water environment, water pollution, mountain flood disasters, reservoir safety, and dam safety.

█ Radar Water Level Gauge is based on electromagnetic wave ranging technology with precise time measurement. The sensor emits electromagnetic waves to irradiate the water surface and receives their echoes, thereby obtaining information such as the distance from the water surface to the electromagnetic wave emission point, distance change rate (radial velocity), azimuth, and height.

As an innovative application of industrial distance-measuring radar in the field of water level measurement, the radar water level gauge has achieved a technological leap for water level gauges towards high precision (millimeter-level), large measuring range (70 meters), high reliability, easy installation, and maintenance-free operation.

Through standard signal interfaces, the radar water level gauge can be connected to computers, PLCs, etc., and can also be connected to corresponding display, recording, and control devices (such as RTUs) to form a water level monitoring system.

Radar flowmeters are mainly used for water measurement in open channels of irrigation districts, serving as data terminals for remote measurement or detection. They are usually selected for measurement in standard sections.

This flowmeter adopts high-precision radar to measure water level and flow velocity, uses its own irrigation channel model to calculate water volume, and makes corrections by considering the impact of the surrounding environment of the open channel.

Application scope: Flow measurement of channels or rivers, suitable for various water qualities including urban sewage, industrial wastewater, irrigation water, drinking water, and seawater.

█ Vibrating Wire Piezometer is a fully sealed submersible intelligent measuring instrument with an all-stainless steel structure design. This product selects a high-performance processing core and a high-precision intelligent transmitter processing circuit, and adopts precision digital temperature compensation technology and nonlinear correction technology, making it a high-precision seepage pressure measurement product. The waterproof cable is hermetically connected to the shell, and the vent pipe is inside the cable, allowing long-term submersible use. Its integrated structure and standardized output signal can meet various complex application requirements. This product can be widely used in informatization construction fields such as water conservancy, environmental protection, and water affairs, including remote measurement and control fields of irrigation districts, hydrology, water resources, water environment, water pollution, mountain flood disasters, reservoirs, and dam safety.

█ A GNSS receiver is a device that receives, calculates, and processes positioning and navigation data from signals of the Global Navigation Satellite System. It can receive signals transmitted by multiple satellites worldwide, and by calculating and processing these signals, it provides high-precision information such as position, velocity, and time. GNSS receivers are widely used in fields including aerospace, geographic surveying, resource exploration, geological disaster monitoring, and intelligent transportation.

█ The Beidou Data Transmission Terminal is an integrated terminal supporting Beidou RDSS/RNSS and 4G communication functions, launched for Beidou communication and 4G communication applications. The M20C-V31 Beidou Data Transmission Terminal integrates functional units such as Beidou multi-frequency antenna, radio frequency, baseband and main control internally, which can realize functions including RDSS positioning, short message communication and RNSS navigation positioning. Meanwhile, the M20C-V31 Beidou Data Transmission Terminal has a built-in 4G module, supporting data transmission via 4G. In addition, this product is equipped with a built-in RTU chip, so it has RTU functions, such as supporting timed data collection and reporting; supporting program version upgrade without losing configuration, which is fully compatible with the configuration of old versions.

The importance of the safety monitoring system for medium and large-scale sluices lies in ensuring the safe operation of sluices, optimizing water resource allocation, enhancing flood prevention and mitigation capabilities, and promoting the modernization of water conservancy project management. The implementation of this system is of far-reaching significance for improving the safety and efficiency of water conservancy projects.

By monitoring the structural status, hydrological data and environmental changes of sluices in real time, potential risks and problems can be identified promptly, and corresponding preventive measures can be taken to ensure the stability and durability of sluices. Furthermore, using data analysis and model prediction, water resource scheduling can be carried out more scientifically, water resources can be allocated reasonably, resource waste can be reduced, and the efficiency of water resource utilization can be improved.

In the field of flood prevention, the monitoring system can provide key information such as accurate water level and flow rate, offering solid data support for flood prevention decisions and effectively reducing losses caused by flood disasters. Ultimately, this system will promote the development of water conservancy project management in the direction of intelligence and informatization, and improve the management level of the entire water conservancy industry and its ability to respond to emergencies.