The automatic monitoring system of sluice and pumping station is mainly derived from the demand for modernized management of water conservancy projects. As an important part of water conservancy projects, sluices undertake multiple functions such as regulating water level, controlling water flow, and preventing floods and waterlogging. However, the traditional sluice management methods have many shortcomings, including equipment aging, non-digitalized information, and lack of system health status information. These problems lead to low management efficiency and difficulty in responding to equipment failures or abnormal situations in a timely manner.

To improve the management efficiency and safety of water conservancy projects and meet the requirements of modern water conservancy, the automatic monitoring system of sluice and pumping station has emerged. This system integrates sensor technology, communication technology, computer technology, and automatic control technology. It can monitor and control equipment such as sluice gates and water pumps in real time, realizing effective management and utilization of water resources in sluice and pumping stations.

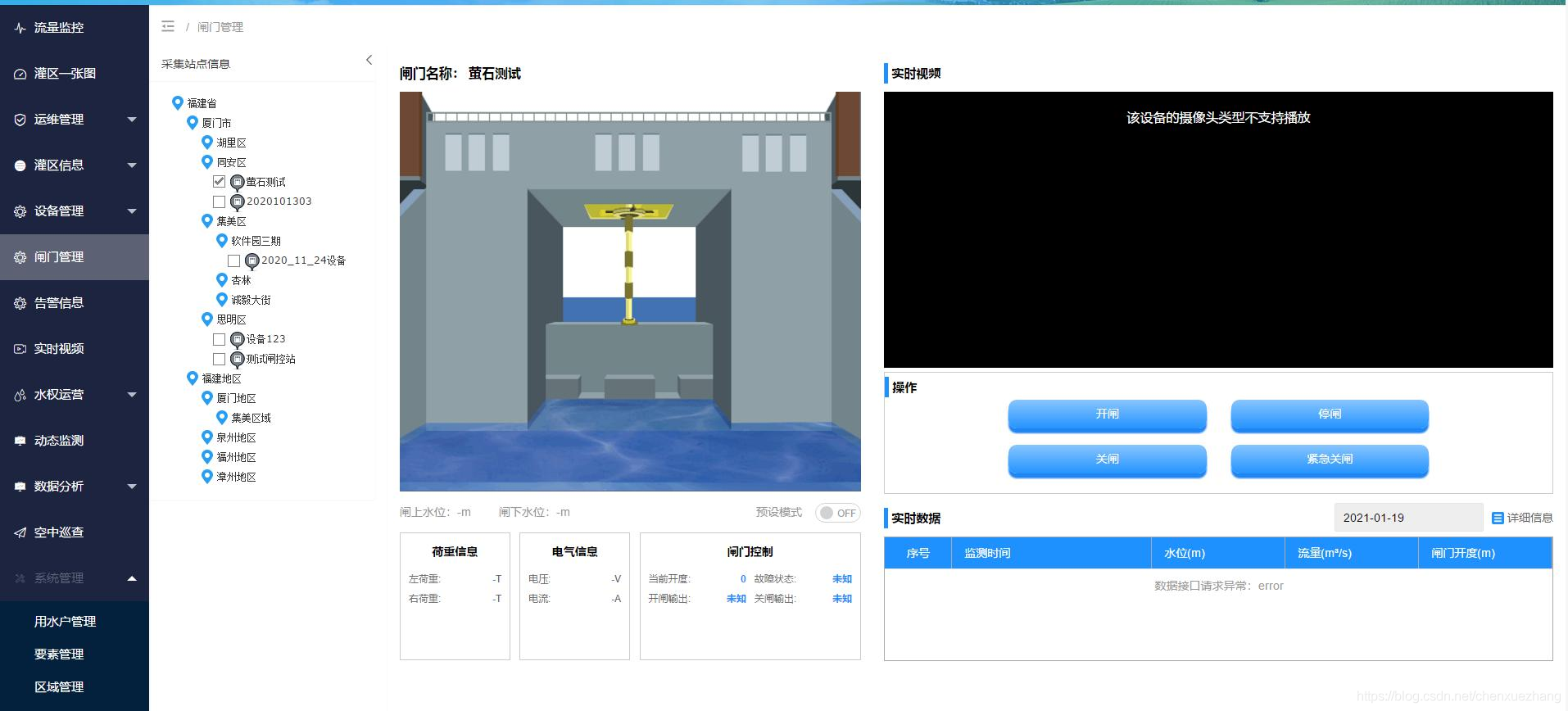

Through sensors deployed at key locations, the automatic monitoring system of sluice and pumping station can collect key data such as water level, flow rate, sluice gate opening, and operating status of pumping station equipment in real time 24 hours a day, and synchronously feed this data back to the management cloud platform. Managers can remotely check the real-time situation through the network-connected management cloud platform at any time, set sluice gate control rules, and realize remote control and adjustment. This improves management efficiency and safety, and achieves effective management and utilization of water resources.

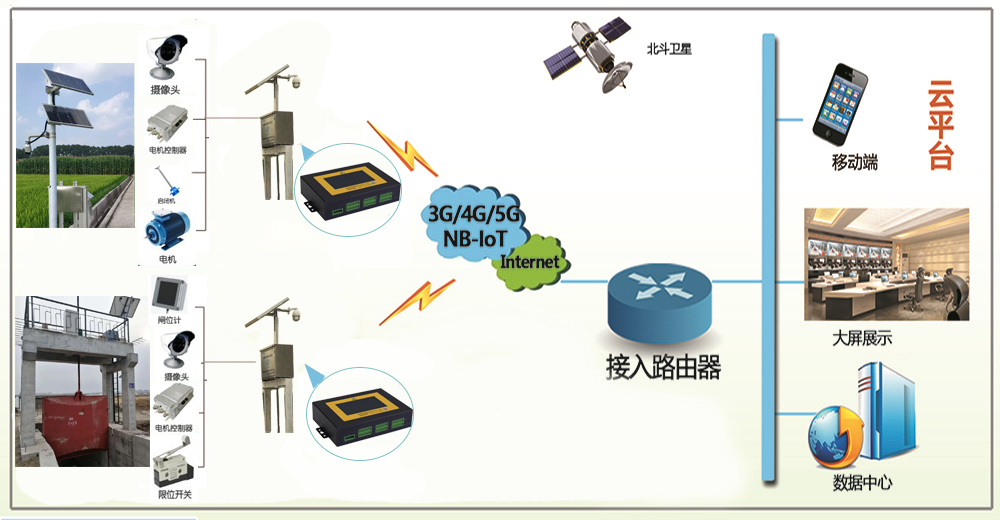

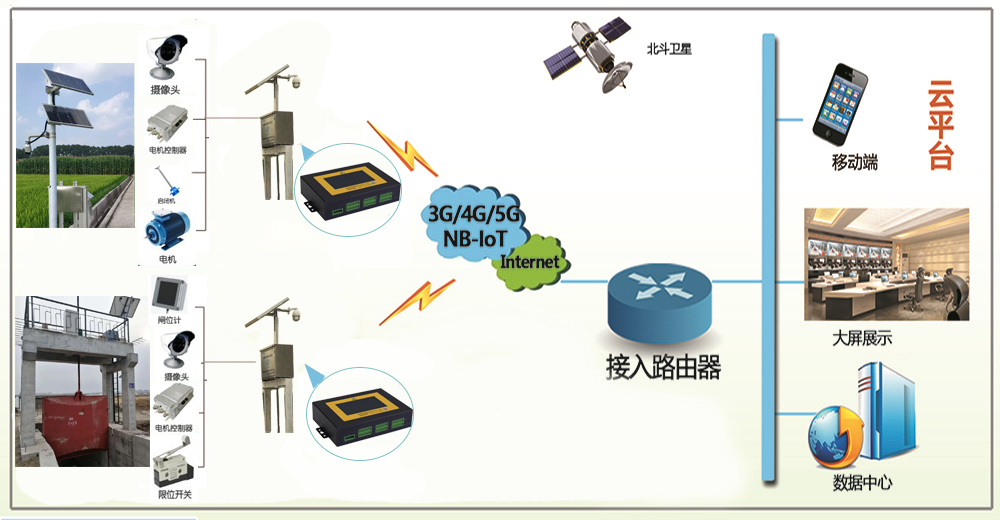

The automatic monitoring system of sluice and pumping station is a system that uses modern information technology to conduct real-time monitoring and management of sluice and pumping station in water conservancy projects. It is mainly composed of three parts: hardware equipment, software system and communication network.

It includes sensors, actuators, data acquisition terminals, monitoring centers, etc. Sensors are responsible for real-time monitoring of key parameters such as water level, flow rate, and sluice gate opening; actuators automatically adjust the on-off status of sluices or water pumps according to instructions from the monitoring center; data acquisition terminals conduct preliminary processing of data collected by sensors and transmit it to the monitoring center; the monitoring center monitors and manages the entire system.

It is responsible for transmitting data collected by hardware equipment to the monitoring center, and at the same time enabling the monitoring center to remotely control the hardware equipment.

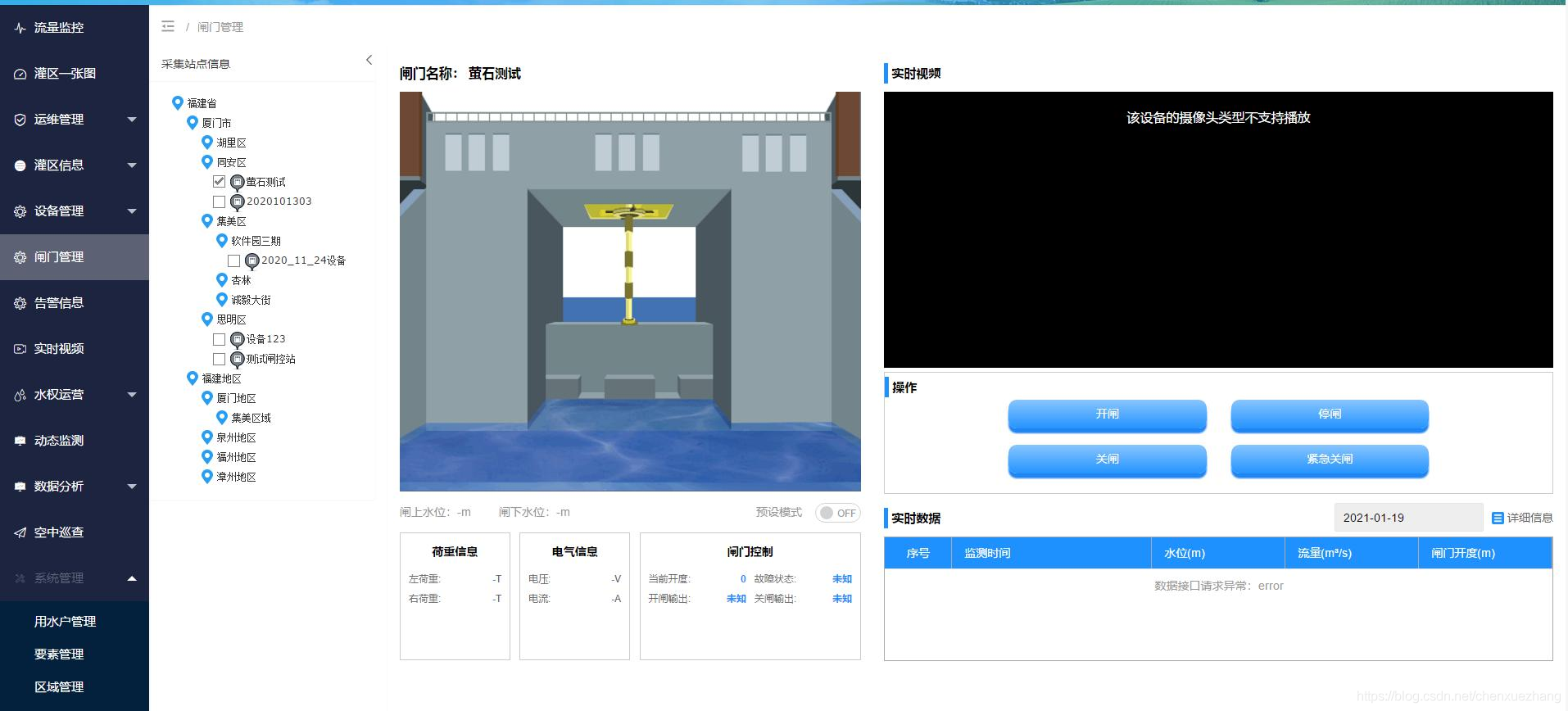

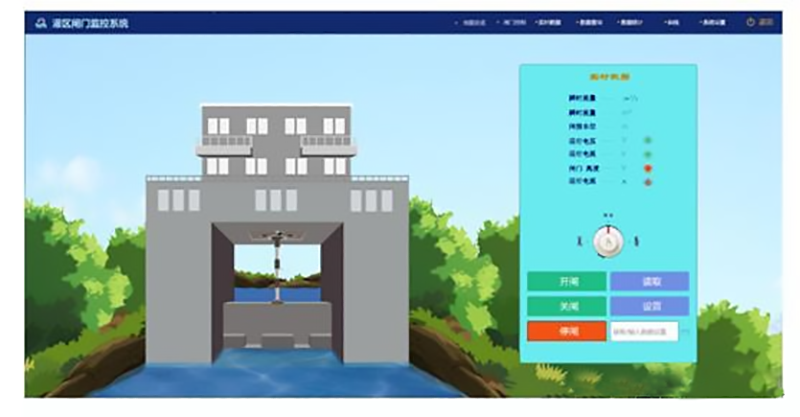

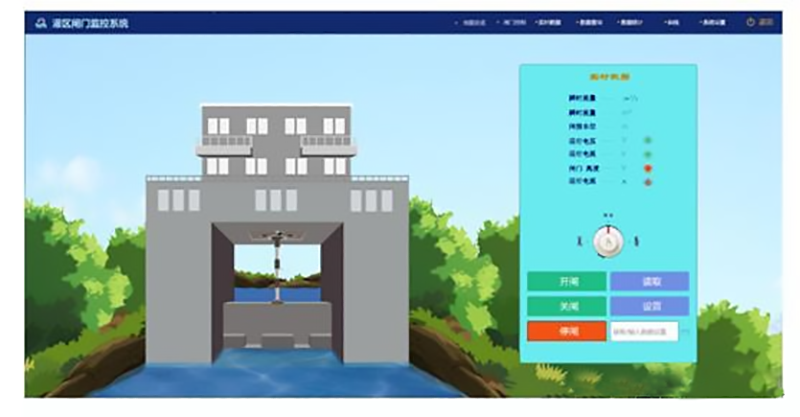

It usually includes functional modules such as data reception, storage, display, analysis, and remote alarm. Through the software interface, users can view the operating status of the sluice and pumping station in real time, receive alarm information, and perform remote control.

Real-Time Monitoring: The system can monitor key parameters of the sluice and pumping station in real time, such as water level, flow rate, and sluice gate opening. It synchronously feeds the data back to the monitoring center, providing data support for management decision-making.

The system is equipped with a remote alarm function. When abnormal parameters or equipment failures are detected, it will automatically trigger the alarm mechanism and notify managers via SMS, email, APP push, and other methods.

Managers can remotely control the on-off status of sluices or water pumps through the software interface of the monitoring center, realizing remote scheduling and control.

The system can record, store, and analyze historical data, generate various charts and reports. This helps managers grasp the operation rules of the sluice and pumping station and optimize scheduling strategies.

The system supports the deployment of network cameras in key locations such as pumping stations, reservoir areas, and water surfaces to realize real-time video monitoring. The video data is synchronously aggregated with monitoring data to the management platform and displayed on the same screen.

Improve Management Efficiency: The automatic monitoring system for sluices and pumping stations can monitor equipment status in real time and enable remote control, reducing the frequency of manual inspection and operation, thus improving management efficiency.

Ensure Safe Operation: With real-time monitoring and automatic alarm functions, the system can promptly detect and address potential safety hazards, ensuring the safe operation of sluices and pumping stations.

Optimize Resource Allocation: Based on real-time monitoring data and analysis results, the system can optimize the allocation and utilization of water resources, enhancing the efficiency of water resource use.

Reduce Maintenance Costs: Through automated monitoring and remote control functions, the system can reduce manual intervention and maintenance costs, and extend the service life of equipment.

The automatic monitoring system solution for sluices and pumping stations can monitor the operating status of sluices and pumping stations in real time, provide early warning and alarm functions, support remote control and management, optimize water resource allocation, improve the efficiency and safety of water conservancy management, and contribute to building a safer, more efficient, and intelligent water conservancy management system.

With advanced sensor technology and data analysis algorithms, the system can accurately capture every subtle change in sluices and pumping stations, ensuring that potential problems are detected in a timely manner and corresponding measures are taken under any circumstances.

In addition, it has strong data processing capabilities, which can conduct in-depth analysis of the collected information and provide a scientific basis for decision-makers, thereby realizing the refined management of water conservancy facilities.

The system's remote control function allows managers to operate and adjust sluices and pumping stations without being on-site, which greatly improves work efficiency and reduces the risks that may be caused by direct manual operation.

Through this solution, water conservancy departments can more effectively respond to various complex water conservancy situations, ensure the rational allocation and utilization of water resources, and provide solid water conservancy support for the sustainable development of society.