When a ship loads or unloads cargo at a port, an inclinometer is required to monitor the hull's inclination angle. Currently, the pendulum-type inclinometer is widely used on bulk carriers, but it has several shortcomings:

Low sensitivity: According to the requirements in CB/T 3376-2005, its sensitivity is no more than 0.4°.

Low accuracy and large division value: Angle display errors are significant due to installation deviations, misaligned base plate fixation, loose fasteners caused by long service life, and rust on swinging parts. This means it cannot accurately reflect the ship's inclination angle, and an inaccurate inclinometer brings great inconvenience and risks to both the shipowner and the port operator.

Difficult correction after error detection: Marine inclinometers are fixed on the ship with screws, making it hard to correct errors once found.

Inability to support draft correction calculations: Due to large errors, it cannot be used to calculate draft corrections based on the displayed angle during the draft adjustment stage.

Inconsistent standards and increased operational risks for ports: Inclinometers are auxiliary equipment of the shipowner, and ports do not have corresponding equipment or standards. Port staff can only judge the inclination angle based on the inclinometer installed by the shipowner. However, inclinometers on different ships have inconsistent standards and accuracy, which increases the difficulty and risks of the staff's work.

Limited measurement range: Traditional marine inclinometers can only display the hull's transverse inclination angle, not the longitudinal inclination angle simultaneously.

Due to the above defects, the pendulum-type inclinometer can no longer meet the needs of modern port production. Chenmai has designed a new instrument for measuring ship inclination angles based on actual demands to meet the needs of both shipowners and port operators.

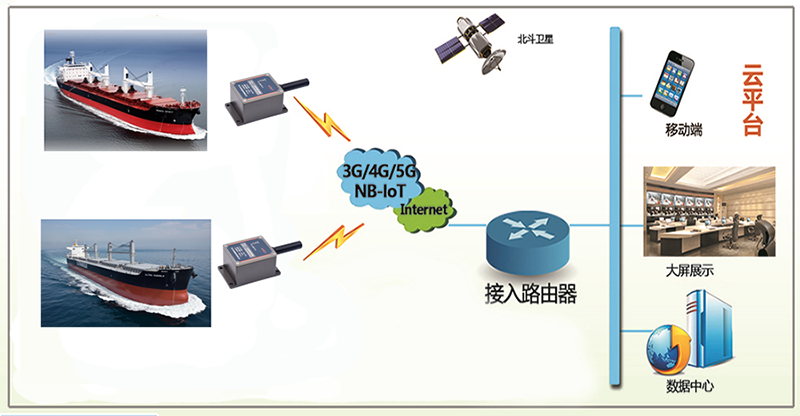

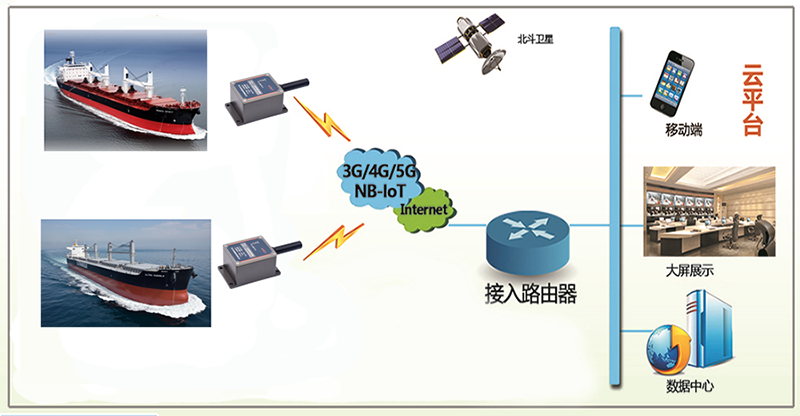

The automatic inclination monitoring system for bulk carriers uses the front-end data collection equipment—including inclination sensors—and wireless communication modules in coordination to achieve 24/7 unattended monitoring. It monitors the inclination status of bulk carriers in real time and transmits the data to the monitoring station via the transmission module. Crew members can check the bulk carrier's inclination status, geometric shape, and position at any time through the system background. When an alert occurs, the system sends early warning information to remind relevant command personnel to prepare for adjustment work. As a typical Internet of Things (IoT) system, it is divided into three layers: the sensing layer, the transmission layer, and the application layer.

Integrated into a mobile and portable device, it is used to detect the ship's inclination angle. Wireless communication is adopted for data transmission with the data processor. The on-board sensors are powered by batteries and feature waterproof and salt-fog-resistant properties.

The data processor collects sensor data in real time from on-board sensors via wireless communication, calculates and outputs the ship's actual inclination angle after analysis. The data processor must be equipped with standard Modbus RS232 or RS485 communication interfaces to facilitate real-time transmission of the analyzed and calculated inclination angle to third parties (e.g., ship unloader PLC or bulk terminal dispatching system) and ensure the safety of the cargo ship.

As a monitoring cloud platform, it displays and processes graphically converted data via large screens, PC terminals, and mobile terminals. At the same time, it stores the data in a database for permanent data storage.

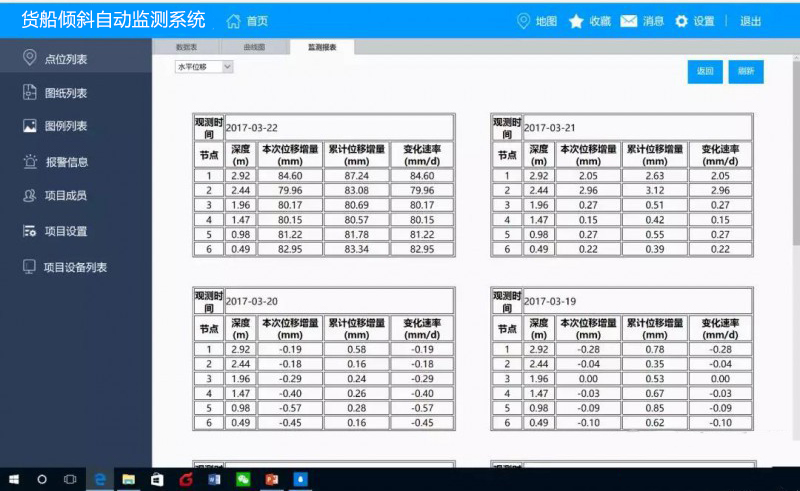

Monitoring Point Management: Enables the display, query, and statistics of cargo ship inclination point information and monitoring network information.

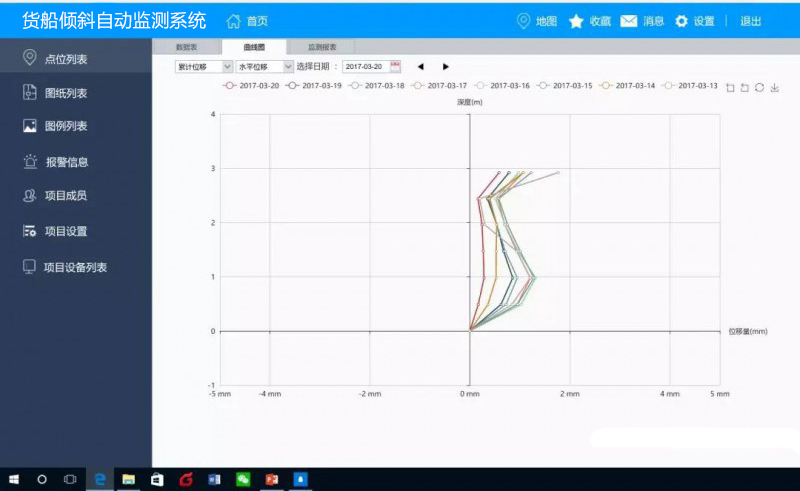

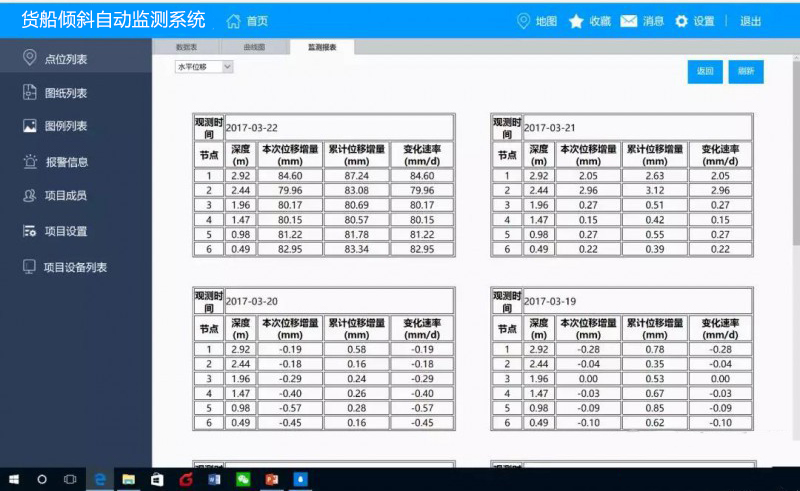

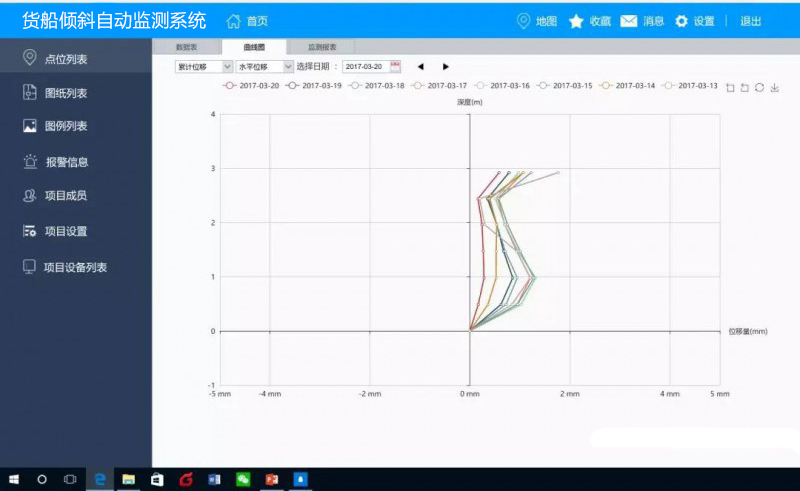

Real-Time Collection of Monitoring Information: Conducts real-time online monitoring of the cargo ship's inclination-related surface settlement, stress and strain, etc., to grasp the ship's inclination changes in real time.

Real-time Monitoring of Monitoring Instrument Status: Through its spatial positioning function, the system can accurately locate the specific positions of various monitoring devices and intuitively display the working status of each device (i.e., whether it is operating normally).

Monitoring Information Management and Analysis: It can retrieve the monitoring values of monitoring stations by time and type, generate corresponding graphs and line charts, and compare them with historical data from the same period.

Automatic Early Warning for Monitoring Points: The monitoring early warning thresholds for different monitoring points can be customized. When the monitoring value of the monitoring equipment reaches the early warning threshold, early warning information will be automatically sent to designated personnel. Timely measures such as personnel intervention, and coordination with the ship unloader PLC or bulk terminal dispatching system can be taken to eliminate potential safety hazards in their infancy.

★ Integrated Service: It provides an integrated software and hardware solution, offering one-stop and considerate services ranging from monitoring, transmission, data service to business application. For the system software, the intelligent monitoring and early warning cloud platform mode provided by Chenmai Wisdom can be selected.★ Integrated Monitoring Station: The integrated structural monitoring station features high reliability, small size, no need for integration, easy installation and low cost. It is dust-proof, waterproof and lightning-proof, and can adapt to harsh working environments such as outdoor rain and humidity.★ Multiple Networking Methods: The system supports multiple communication and transmission methods including 2G/3G/4G/5G mobile communication, SMS alarm and Beidou satellite.★ Cloud Platform: The platform enables convenient device access, allowing real-time viewing of device monitoring data and operating status, and easy realization of remote device monitoring and management. It provides a series of standardized data services covering the entire process from data collection, transmission, processing, compilation, storage, analysis, and presentation to data push. It supports rapid deployment and launch, with elastic scalability, and enables both universal and customized business applications.

This solution addresses issues associated with manual cargo ship inspections, such as heavy workload, poor timeliness, continuity and accuracy, and lagging inspection data analysis.

By leveraging IoT technologies for sensing, transmission, perception and application to monitor cargo ships, it prevents incidents that threaten the safety of cargo ships, the surrounding environment, personnel and property—such as ship inclination and deformation. This enables command departments to quickly develop solutions, thereby avoiding or mitigating losses caused by cargo ship damage.

It realizes real-time dynamic monitoring of bulk carrier inclination, strengthens safety supervision over bulk carrier inclination, keeps bulk carriers in a real-time and controllable safe state, and assists managers in making scientific decisions.