Traditional bridge monitoring systems typically require the installation of a large number of sensors and data acquisition devices in bridge structures. These devices are bulky, complex to deploy, and rely on external power supply, resulting in high monitoring costs and making large-scale promotion difficult. In addition, traditional monitoring methods tend to focus on the inspection of bridge appearance, with limitations in detecting internal defects. Restricted by inspection frequency, they cannot achieve full-life-cycle tracking of bridge operation status.

To solve these problems, lightweight monitoring technology has emerged. Lightweight monitoring systems adopt miniaturized, low-power-consumption sensors, combined with wireless communication technology and intelligent algorithms, enabling real-time and accurate monitoring of bridge structures while significantly reducing equipment deployment and maintenance costs. These sensors are small in size and light in weight, suitable for various types of bridge structures, and can monitor the health status of bridges in multiple dimensions, including key parameters such as bridge deflection, vibration, strain, and temperature.

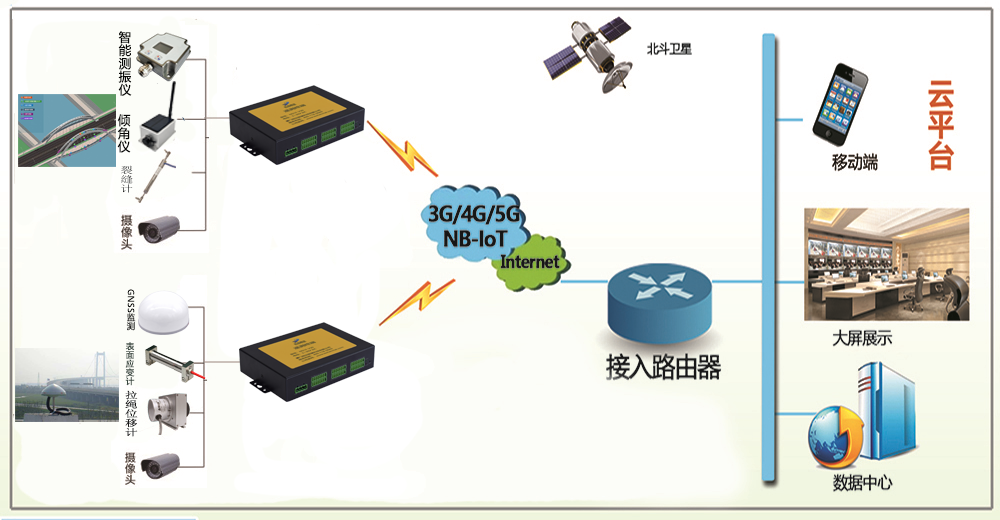

Through wireless communication technology, the lightweight monitoring system can transmit real-time data collected by sensors to the cloud platform. Combined with intelligent analysis algorithms, it conducts real-time evaluation of the bridge's health status and issues timely early warning information when potential risks are detected.

The lightweight structural safety monitoring system for bridges scientifically deploys various types of monitoring devices, integrating IoT, big data, GIS, BIM modeling, and other advanced technologies. It achieves real-time online monitoring of key bridge parameters including temperature, strain, cable displacement, static deflection, inclination angle, acceleration, and wind speed/direction. Leveraging functional modules such as comparative analysis, correlation analysis, modal analysis, and spectrum analysis, the system conducts comprehensive monitoring, in-depth analysis, and timely early warning of the bridge's operational health status.

Additionally, the system integrates video monitoring and overload monitoring & statistical analysis capabilities. It captures and analyzes overload vehicles' key information such as weight, type, passage time, and origin. It provides bridge authorities with data support and auxiliary decision-making for critical events including bridge operational health, special meteorological conditions, and overload supervision. Furthermore, it offers professional consulting and advisory services for daily bridge operation management, inspection, and maintenance.

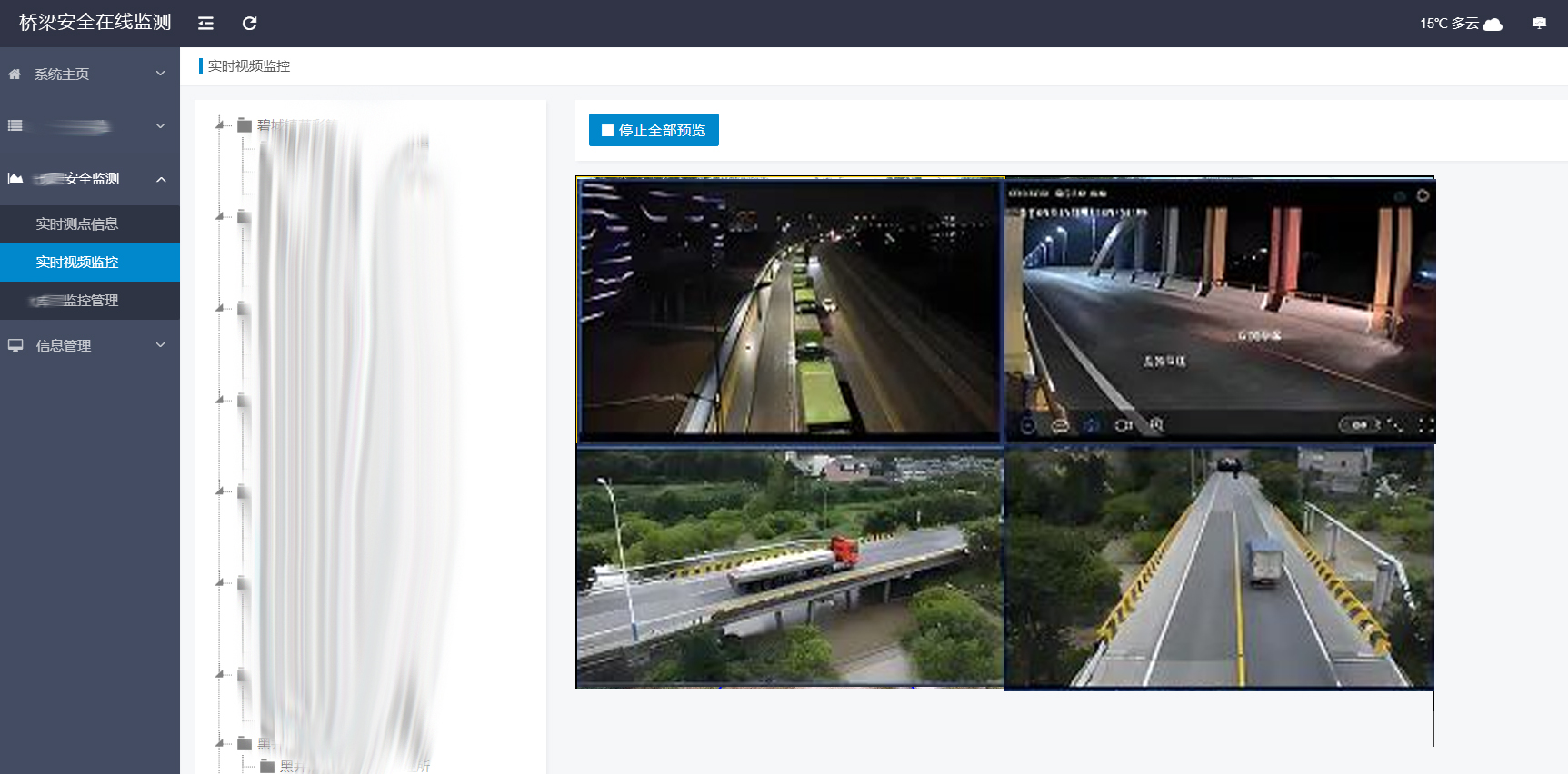

The system supports map-based display and access to real-time online monitoring data, including quick query and visualization of monitoring devices, presentation of monitoring data, display of alarm status, and real-time rendering of monitoring data curves.

Through the display functions on the system's main interface, users can check the location and operational status of devices, and obtain real-time monitoring data on the bridge's structural parameters (such as displacement, settlement, inclination, acceleration, amplitude, and frequency) as well as environmental conditions and structural responses. Upon detecting any abnormalities, the system immediately and automatically pushes early warning information to ensure timely handling of potential issues.

Timely Alarm

Various types of sensors installed on the bridge surface monitor structural parameters such as displacement, settlement, inclination, acceleration, amplitude, and frequency. These parameters directly reflect the bridge’s structural status, including whether deformation exists and whether the stress is balanced. The collected data is transmitted to the relevant software system, enabling comprehensive real-time monitoring of the entire bridge structure.

When data exceeds the preset alarm thresholds, the system automatically issues alarm notifications of different levels based on the early warning data. It supports multi-level alarm configuration and delivers alerts to relevant leaders and responsible personnel through multiple channels, including software pop-up windows, emails, SMS, and acousto-optic alarms.

Remote Video Monitoring

The system provides real-time video surveillance, allowing users to view on-site footage in real time via monitoring terminals. Meanwhile, users can remotely control on-site camera lenses and pan-tilt-zoom (PTZ) devices through the software, adjusting the aperture, focal length, zoom level, and viewing angle as needed. This meets users’ requirements for multi-dimensional on-site video monitoring and ensures the safe operation of the bridge.

Adopting a B/S (Browser/Server) architecture, the system allows users to access it anytime and anywhere to view real-time bridge data and historical records. Meanwhile, the system can automatically generate reports, facilitating efficient management of bridge data for users. Through tracing and in-depth analysis of monitoring data, the system can timely identify potential safety hazards of bridges and provide accurate diagnostic reports. This assists bridge management authorities in better understanding the operational status of bridges and formulating scientific maintenance plans.

Under applicable conditions, innovative concepts and methods in the lightweight structural monitoring and management of bridges are integrated into system development. It achieves the integration of data and graphics, as well as the combination of GIS and mathematical models, intuitively presenting the results of scientific calculations through 3D scenarios and dynamic visualization

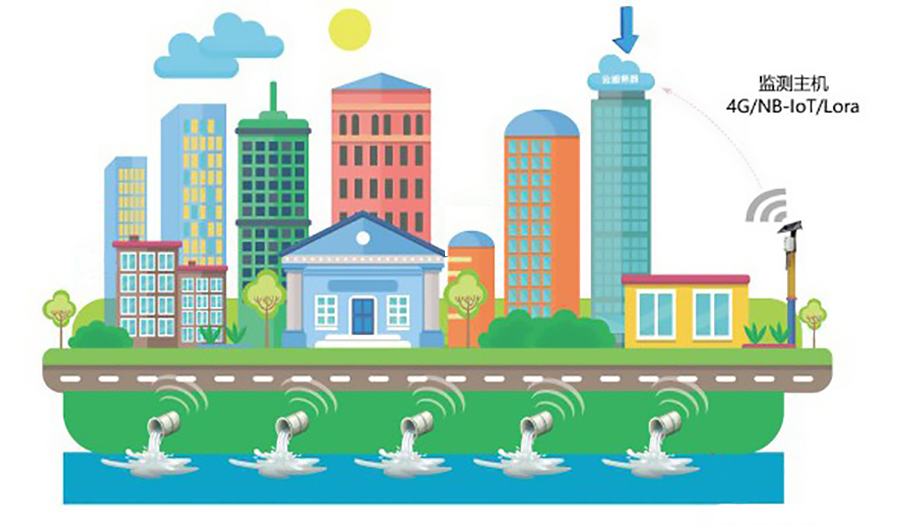

Integrating the functions of a traditional telemetry terminal, 2G/3G/4G full-network connectivity, NB-IoT short-message wireless long-distance transmission, and LoRa wireless short-distance transmission, this device delivers comprehensive capabilities including data collection, storage, transmission, display, control, and alarm for hydrology, water resources, geological disaster monitoring, meteorology, and other fields. It also supports GNSS positioning.

Adopting a high-performance industrial-grade 32-bit communication processor and industrial-grade wireless module, the product is supported by an embedded real-time operating system (RTOS). It provides a rich interface suite, including RS232, RS485, SDI, Ethernet ports, 4~20mA and 0~5V analog inputs, digital inputs, relay outputs, and digital outputs, enabling compatibility with diverse application requirements.

Widely used in informatization projects, it is particularly suitable for remote monitoring and control scenarios such as hydrology, water resources, water environment, water pollution, flash flood disasters, reservoir safety, and dam safety.

Integrating the functions of a traditional telemetry terminal and a 4G router, this device delivers comprehensive capabilities including data collection, storage, transmission, display, control, and alarm for hydrology, water resources, geological disaster monitoring, meteorology, and other fields.

Adopting a high-performance industrial-grade 32-bit communication processor and industrial-grade wireless module, the product is supported by an embedded real-time operating system (RTOS). It provides a versatile interface suite, including RS232, RS485, SDI, Ethernet ports, 4~20mA and 0~5V analog inputs, digital inputs, relay outputs, and digital outputs, enabling it to meet the requirements of diverse applications.

A GNSS (Global Navigation Satellite System) receiver is a device that receives, processes, and resolves signals from global navigation satellite systems. It can capture signals transmitted by multiple satellites worldwide, and through signal resolution and processing, provide high-precision information such as position, velocity, and time (PVT).

Widely used in aerospace, geodetic surveying, resource exploration, geological disaster monitoring, intelligent transportation, and other fields.

Independently developed by Chenmai Wisdom, this low-power wireless inclination sensor is a remote NB-IoT dual-axis device specifically designed for industrial applications requiring periodic attitude angle monitoring in outdoor environments without power supply or continuous measurement needs.

The sensor operates in standby mode for extended periods, with an ultra-low standby power consumption of only 0.4mA. It can upload data to the relevant platform at user-configurable intervals based on preset wake-up settings, allowing users to monitor the status of measured objects via the network service platform without on-site surveys.

Users can set angle and acceleration thresholds. If the sensor detects a sudden angle deviation or acceleration exceeding the preset thresholds, it will automatically wake up and immediately transmit alert information.

Primarily used for condition monitoring of various large-scale engineering facilities and equipment, this product enables "real-time" monitoring of the triaxial inclination status of objects.

Developed specifically for Beidou and 4G communication applications, this integrated terminal supports Beidou RDSS/RNSS and 4G communication functions.

The M20C-V31 Beidou Data Transmission Terminal internally integrates functional units such as a Beidou multi-frequency antenna, RF (Radio Frequency) module, baseband module, and main control unit. It enables core capabilities including RDSS positioning, short-message communication, and RNSS navigation positioning.

Additionally, the M20C-V31 model is equipped with a built-in 4G module, supporting data transmission via 4G networks. Furthermore, it incorporates an RTU (Remote Terminal Unit) chip, thus inheriting RTU functionalities: scheduled data collection and reporting; firmware version upgrades with configuration retention; and full compatibility with legacy configurations.

The lightweight structural safety monitoring system for bridges not only improves monitoring efficiency and accuracy but also effectively reduces the operation and maintenance (O&M) costs of bridges. Through this advanced monitoring technology, the safety performance of bridges can be significantly enhanced, ensuring the stability and durability of bridge structures.

Furthermore, the system plays an important role in promoting highway informatization. It provides real-time and accurate data support for highway management departments, enabling more intelligent and refined bridge management.

Typically, such a monitoring system includes various sensors and data acquisition devices that continuously collect bridge operation data 24/7, including but not limited to key indicators such as stress, strain, displacement, and vibration. Through the analysis of these data, potential issues and damages of bridges can be detected in a timely manner, allowing preventive maintenance measures to be taken to avoid major accidents.

Meanwhile, the lightweight design facilitates easier installation and maintenance, reduces additional loads on the bridge structure, and further improves the reliability of the monitoring system and the overall safety of the bridge.